What You Need to Know About Air Compressor Pressure Regulator With Gauge

Pressure regulators are present in different working environments and fields. As these are significant devices, operators would need to secure the best and durable one that they can get. . This is where the purchase of Air Compressor Pressure Regulator With Gauge is necessary. If this is your first time, you will need a guide of factors to consider to ensure you get the suitable one for your needs. Keep on reading to learn the basics of pressure regulators.

The Basics of Air Compressor Pressure Regulator With Gauge

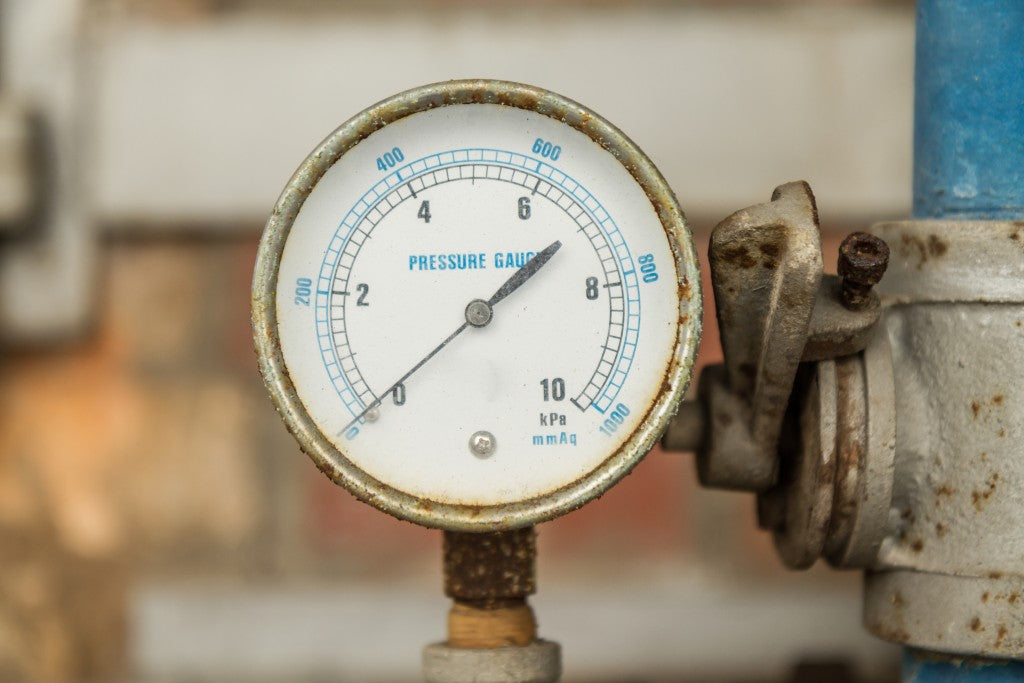

One of the essential air compressor accessories you need for your system is the pressure regulator gauge. Like any other accessories, this plays a significant role in your system which would make your process more efficient. It works to regulate air pressure as necessary and prevents you from overfeeding pressure to your air tools. Remember that compressed air can be dangerous, so you need to ensure you manage its flow correctly.

Indeed, the works of air compressor pressure regulators with gauges are indispensable. Thus, it is necessary to find the best and suitable air compressor pressure regulator with a reliable gauge for excellent performance. However, choosing pressure regulators may be challenging when you are new to it and has little knowledge.

That said, it is helpful to gather data and assess available options based on relevant factors. This may include materials used, temperature, operating pressures, flow requirements, and even size and weight. These are some of the primary factors you need to consider as you look for a pressure regulator gauge for your air compressor.

Materials

An ideal pressure regulator should be durable, reliable, and is able to handle extreme applications, fluids, and environments. Hence, the materials used are a significant factor to consider.

The standard regulators today are made up of brass, aluminum, plastic, and stainless steel. If you are looking for economical and suitable for various applications, brass materials are available. If you are considering weight, an aluminum-made regulator is ideal. Meanwhile, if plastic regulators may be a viable option if you are looking for a cheaper alternative.. However, stainless steel alternatives are also available when you’re dealing with corrosive fluids and environments.

Temperature

Another factor to consider is the temperature. When looking for one, it has to fit and function correctly at the estimated temperature. The regulator must fit precisely as well, as it will affect your overall process and flow capacity.

Operating Pressures

Before choosing your next pressure regulator, it is necessary to assess the operating pressures, specifically the inlet and outlet pressures. Make sure to check the requirement and variation in outlet pressure and fluctuation in the inlet pressure.

Flow Requirements

The next thing to consider is its flow requirements. Start by assessing the maximum flow requirements of your application and how it varies. You may also need to consider the port for the proper fitting.

Size & Weight

Size and weight is also a vital factor especially when space is limited. As for the weight, the material considerations can affect. Make sure to consider the thread sizes of port, mounting options, and other components that may impact the size and weight.

Air Compressor Pressure Regulator Leaking: Is it a problem?

It is always a great choice to have the best pressure regulator possible. This will not only secure a smooth work process flow, but you also get the most out of your investment. However, the best pressure regulator that you purchased would still be able encounter problems if you are not aware of the proper maintenance.

One of the common problems encountered by the operators is air leaks. However, the leaking may be either on purpose for regulators or a problem with your regulator. As we all know, air pressure can be powerful. . If your regulator is a relieving type, then leaking from it may be on purpose. It allows downstream pressure to process as needed. Meanwhile, if your regulator is not self-relieving and there is a dial-down on air pressure and the application is pressure-sensitive, then there might be a problem in the line.

When this happens, it is best to assess and check whether air compressors and parts of the pressure regulator are the problems. Also, conduct regular maintenance and don't jump to conclusions unless you thoroughly assess whether you need to replace parts or better get a new pressure regulator.

Ensure Reliable Pressure Regulator and Air Tools with Le Lematec!

Finding a reliable air compressor adjustable pressure regulator may be challenging, but you can surely land with the best one with the correct list of considerations and understanding. Start browsing through our air tool collection page, and search for the air compressor pressure regulator with gauge you need for your requirement. Excellent work becomes much more achievable with the use of Le Lematec tools.